How easy can material handling systems be? Actually they can be very simple. All you need are a few different modules. Thereby powerful and reliable intralogistics systems can be created. Is a control such as a PLC required? No, in future not anymore. If each conveyor module has its own intelligent control box, an intelligent algorithm can set up the communication between the modules and enable an extensive functionality.

Flexibility is another advantage of this innovation. It is very easy and extremely quick to implement changes in function or layout. It doesn’t matter whether you want to expand the system or just change it, there is no programming knowledge needed, that is real plug and play. In addition to the intelligent control, it also needs an intelligent, configurable mechanic construction set which also makes it possible to reuse conveyor modules.

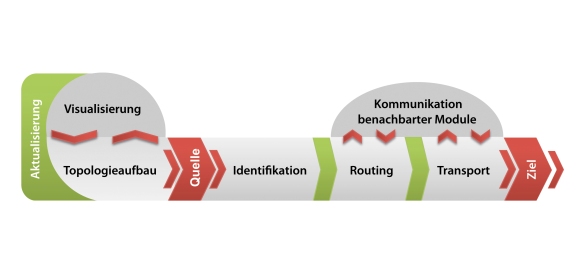

How does it work? The software automatically detects the current layout, fully autonomous. This generates the base for an independent recognition of conveying routes. This is in turn the base for the automatically configuration of the material flow computer. Anyway the material flow computer can not be imagined as in the classical and central sense. The material flow functionality is represented by the decentralized intelligence. Thus, complex conveyor systems that are extremely fast and very easy to set up and to operate are coming up.

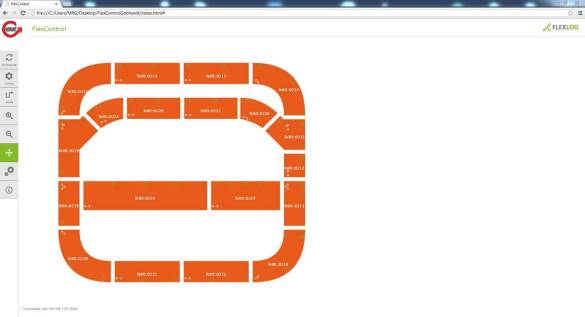

Also the visualization in this system is intelligent. The system reacts to every change in the status or even in the layout. The visualization is updated immediately – of course without any programming. The surface also provides information regarding the error handling, the maintenance or the status of the sensor and the actuator.

What are the benefits? First of all there is a massive reduction of the commissioning time. All modules are delivered preconfigured and ready for plug & convey.

Thereby the material flow can be easily set up, but also changed later without any problems. This is ideal for the intralogistics, the production and the assembly. Just if you think about Lean / Kaizen activities in companies, this system offers incredible benefits. Where it was previously necessary to plan complicated reconstructions, you can now independently optimize and adjust the material flow with the GEBHARDT System 600 without much preparation. The same applies to extensions of the system.

Due to the decentralization, the availability of the system is also increased because the downtimes can be minimized. Defective modules can be easily replaced in a few minutes.

This conveyor system enables completely new possibilities. In times of Industry 4.0, Internet of Things and increasing flexibility requirements, the GEBHARDT System 600 enables already today futuristic functions.